No PCB Order is Too Small or Too Large

When it comes to purchasing printed circuit boards, building a relationship with Advanced Circuits can help you not only today, but in the long run. Quantity doesn't matter, as we don't require minimim printed circuit board orders. We will make as few as one PCB as either a Standard Spec or Custom Spec order. No order is too small for us! You can rely on us to provide the same exceptional service on any size printed circuit board order.

Quality is the same. All Standard Spec and Custom PCB orders go through the same rigorous fabrication and quality check process.

For any size printed circuit board order you will enjoy the same quick turn advantages. We can produce your Custom Spec order, including multi-layer PCBs, just as quickly as our Standard Specs orders -- even manufacturing your PCBs in one day if needed.

What’s the Difference?

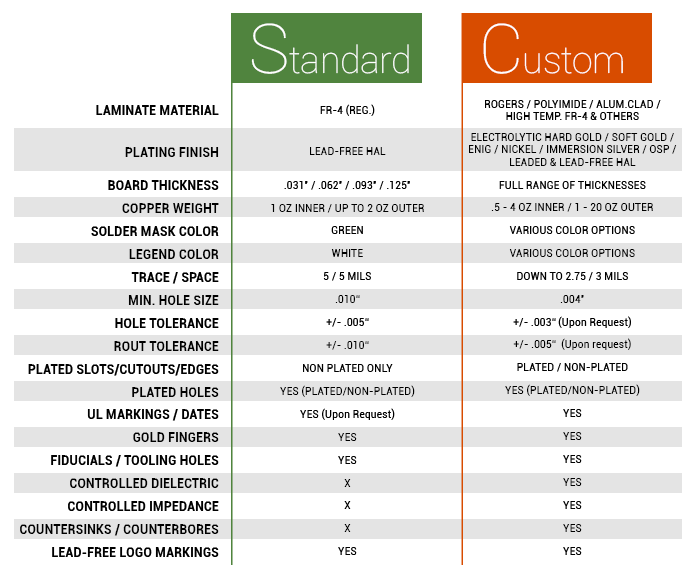

Standard & Custom Spec order options include:

Please Note: 94V-0 is added upon request at the time of order entry or if noted in files. Added markings contingent on available space on boards. Holes will be plated if no specifications provided. Default Solder Mask color is Green unless another color option is requested. Default Legend (Silkscreen) color is White unless another color option is requested.

See Complete List of Capabilities

See Complete List of Capabilities

- No Tooling NRE Charges on Standard Spec. In addition, when you re-order your Standard Spec with no changes and upgrade to Custom Spec we waive the tooling charge again.

- Electrical Test: A One-Time Charge. If you pay as a Standard Spec you don’t pay again… even for a fixture when upgrading to Custom Spec.

Whether you have a need for a double sided or a multi-layer PCB, Advanced Circuits is your one stop printed circuit board provider. Deciding whether you need to order your printed circuit board as a Standard Spec or as a Custom Spec board is simply a matter of looking at the specs. Standard Spec boards (PCBs) are inspected to IPC Class 2 Standards and Custom Spec Boards are inspected to either IPC Class 2 or Class 3 depending on what option is chosen.

Already registered? Click Here to log-in»

Already registered? Click Here to log-in»

Standard Specs for Printed Circuit Boards include:

- Plated or Non-plated holes (if no specifications provided, holes will be plated)

- Non-plated slots and cutouts (plated available on Custom Spec orders)

- Green soldermask

- FR4 (regular)

- White legend (silkscreen)

- 1 oz. Cu. Inner layers / Up to 2 oz. Cu. Wt. on outer layers

- Overall thickness .031" .062", .093", or .125"

- Trace/Space to 5/5 mils

- Gold fingers

- Lead-Free HAL Solder plating finish

- Rout Tolerance +/- 0.010”

- Hole Tolerance +/- 0.005”

- Minimum Hole Size .010"

- Fiducials and/or Tooling Holes

- UL markings & date codes (94V-0 is added if requested at time of order entry or if noted in files. Contingent on available space on board)

- Lead-Free logo markings on boards (Contingent on available space on board)

Custom Specs for PCB's include:

- Plated or Non-plated holes (if no specifications provided holes will be plated)

- Non-plated or plated slots/edges and cutout's

- Various laminates including high temp (tg) FR4, Rogers, Polyimide, and Aluminum Clad

- Full range of finished board thicknesses

- Different soldermask colors (default green)

- Different silkscreen (legend) colors (default white)

- Trace / Space: Down to 2.75 / 3 mils

- UL markings & date codes (94V-0 is added if requested at time of order entry or if noted in files. Contingent on available space on board)

- Lead-Free logo markings on boards (Contingent on available space on board)

- Controlled Dielectric and/or Controlled Impedance

- Cu. Wt. 0.5 – 4 oz. Inner / 1 - 20 oz. Cu. Outer Layers

- Countersinks/Counterbores

- Fiducials and/or Tooling Holes (no additional charge if requested)

- Minimum Hole Size .004"

- Hole Tolerance +/- 0.003” (if requested)

- Rout Tolerance +/- 0.010" (+/- .005" upon request)

- Electrolytic Hard Gold plating finish (total board or gold fingers only) and other plating finishes to include ENIG, Soft Bondable Gold, Nickel, Immersion Silver, and OSP. Also HAL available in both leaded and lead-free solder finishes.

See what our customers have to say about our excellent customer service and reliability:

I am certain we are not one of your biggest customers. However, we are always made to feel we are. The customer service you provide in unparalleled. You are always ready to help with whatever it is we need. And for this, we thank you.” - L.C. Hovland Company

I am certain we are not one of your biggest customers. However, we are always made to feel we are. The customer service you provide in unparalleled. You are always ready to help with whatever it is we need. And for this, we thank you.” - L.C. Hovland Company