One- Stop Shop for PCB Manufacturing

Advanced Circuits' "one-stop-shop" approach to PCB manufacturing is why many engineers rely on us for all of their printed circuit board needs; from the simplest 2 layer PCBs to the most complex 40 layer PCBs. Click here to review Advanced Circuits' expanded PCB manufacturing capabilities.

Manufacturing Multilayer PCBs (Up to 40 Layers)

The demand for multilayer printed circuit boards has been on the rise. The drive for electronics to be smaller, faster, and more powerful has made the multilayer PCB much more popular. The ability to create multilayer boards opens up a world of possibilities allowing the engineer to create more densely populated circuit boards which allows miniaturization. This is a huge benefit that double sided boards are not able to offer.

View Capabilities & Get Quote →

The First Process in the Production of a Multilayer PCB is Making the Inner Layer Core

The process begins by selecting a sheet of laminate that is the correct thickness and covered with Cu foil of the required weight. Both Sides of the core are covered with a UV sensitive, dry film resist that is “hot-roll” laminated in place. Using film created from the electronic data, the inner layer circuitry and planes are transferred to the resist.

The clear areas of the film allow the UV light to make contact with the resist, hardening it so it will adhere to the core surface. The resist that is protected from the light will be developed away in the next process. Developing off the resist exposes the Cu areas that will be removed from the core’s surface.

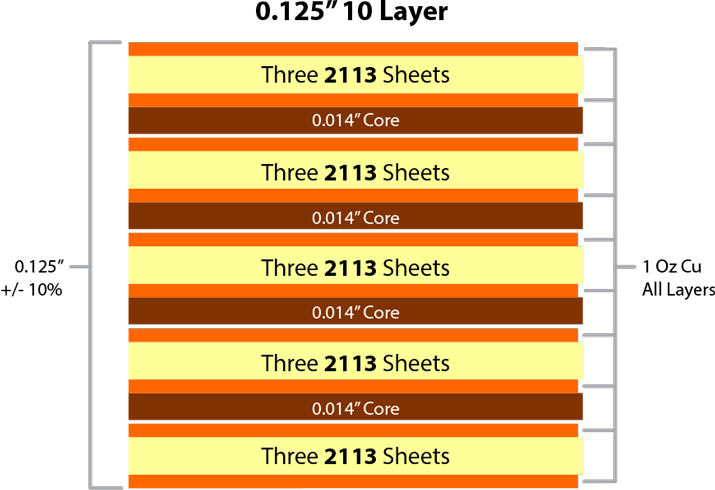

Multilayer PCB Lamination

Materials used in the lamination process include: inner layer core, sheets of “prepreg” (woven glass cloth with epoxy resin), and sheets of Cu foil. Tooling holes in each sheet of materials and core are used to align them as they are stacked up. For a 4 layer board, the bottom would be a sheet of foil, followed by a specific number of sheets of prepreg, the the inner layer core. It is followed by more prepreg and finally the top sheet of foil. The stack of panels is built on a heavy metal plate and when it is completed a top plate is added creating a “book”. The book is then moved to a heated hydraulic press.

Materials used in the lamination process include: inner layer core, sheets of “prepreg” (woven glass cloth with epoxy resin), and sheets of Cu foil. Tooling holes in each sheet of materials and core are used to align them as they are stacked up. For a 4 layer board, the bottom would be a sheet of foil, followed by a specific number of sheets of prepreg, the the inner layer core. It is followed by more prepreg and finally the top sheet of foil. The stack of panels is built on a heavy metal plate and when it is completed a top plate is added creating a “book”. The book is then moved to a heated hydraulic press.

Pressure, heat, and a vacuum are applied over a 2 hour period forcing the resin from the prepreg to become elastic and flow across the core and foil surfaces. Once cured, the resin will join the glass sheets, core, and foil together into the multilayer PCB pannel.

Choosing the Right Vendor for Multilayer PCBs

The processes to manufacture multilayer printed circuit boards require specialized equipment and a significant commitment to operator training, not to mention the financial consideration. This explains why some fabricators have been slower to enter the multilayer manufacturing market than others. Advanced Circuits can provide the expanded capabilities to support advanced printed circuit board designs with demanding requirements including laser drilled microvias, cavity boards, heavy copper up to 20 oz., via-in-pad, microwave & RF boards, up to 40 layers and others.