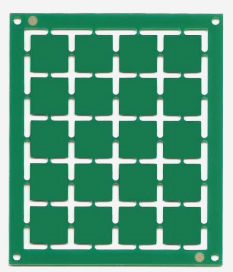

You may wish to request that your PCBs be delivered as arrays. Below please find instructions and descriptions on why we offer this service. Let us know if you have questions, especially if you are requesting small boards or you are placing a large order. We offer exceptional customer service so our customers can avoid manufacturability issues before the PCB production process begins.

What are PCB Arrays?

For large quantity orders or very small boards you might want to consider having your boards supplied in pallet form (array, or sometimes called "panelized", "stepped out", "palletized" and "rout and retain"). Many assembly houses request that printed circuit boards be built on panels with a border. Deciding how many boards can fit on a panel can be quite complicated. We suggest that you consult with your assembly house regarding any suggestions or requirements that they may have. Learn about our Quickturn, Small Quantity Assembly Services >>

For large quantity orders or very small boards you might want to consider having your boards supplied in pallet form (array, or sometimes called "panelized", "stepped out", "palletized" and "rout and retain"). Many assembly houses request that printed circuit boards be built on panels with a border. Deciding how many boards can fit on a panel can be quite complicated. We suggest that you consult with your assembly house regarding any suggestions or requirements that they may have. Learn about our Quickturn, Small Quantity Assembly Services >>

There are two options available for accommodating the separation of the boards after assembly. The boards can be scored on both the top and bottom surfaces allowing the boards to be fractured apart by applying a bending stress to the score lines. This is not recommended for small parts or those with fragile components close to the board edge. The other option is to tab-rout the boards. This process leaves tabs of material between adjacent boards and between the boards and the frame. The boards are then separated after assembly by breaking these tabs or cutting them away.

When looking into how you can combine the boards into panels, we prefer that the files be submitted already panelized. That way you can add fiducials, tooling holes, etc. exactly where you need them. In the absence of any specifications regarding the array set-up we will use the following guidelines: View Standard PCB Array Guidlines Drawing >>

Application notes for scored arrays:

Application notes for scored arrays:

-

The dimensions of the individual boards should include the beveled edge that results from the scoring process. It is best if you can allow .025" from the score line to any copper; we require .015" for boards .062" thick or less, .020" for .093" or less and .025" for .125" or less.

-

When determining how close to the score you can place components, you need to consider the de-panelization method, fragility of the components and parts placement method of each component. In most cases, your assembly house can provide the most accurate information in terms of scoring for components. Learn more about our Quickturn, Small Quantity Assembly Services>>

-

It is best if you can leave at least .020" from any conductors on the inner layers to the edge of the board.

Note: Score lines will continue all the way across your array. If the score line cannot be continuous across the entire array (for example, if a part is rotated in part of the array) this will increase process time and price.

I have been using Advanced Circuits for years. I mainly used it in my previous job with Boeing on Maui. One of my coworkers there turned me on to your services. One of the big advantages to us was the free checks before we sent the boards for fab. This is still true as a major benefit. My two boards I just sent for fab had global issues with the soldermask and silk screen. I wouldn't have found the issues without your DFM tool."

I have been using Advanced Circuits for years. I mainly used it in my previous job with Boeing on Maui. One of my coworkers there turned me on to your services. One of the big advantages to us was the free checks before we sent the boards for fab. This is still true as a major benefit. My two boards I just sent for fab had global issues with the soldermask and silk screen. I wouldn't have found the issues without your DFM tool."