Helping our customers reduce the cost of their printed circuit board projects is always a top priority. Advanced Circuits makes it easy to understand the pricing factors within our quoting structure to help printed circuit board design engineers stay within certain parameters from the start if they are looking for ways to reduce cost.

We offer three low-cost, quickturn prototyping options for 2 and 4 layer PCBs: BareBones, $33 Each, and $66 Each. These special pricing options are fabricated using the same state-of-the-art equipment as our Full-Service offering with few design restrictions.

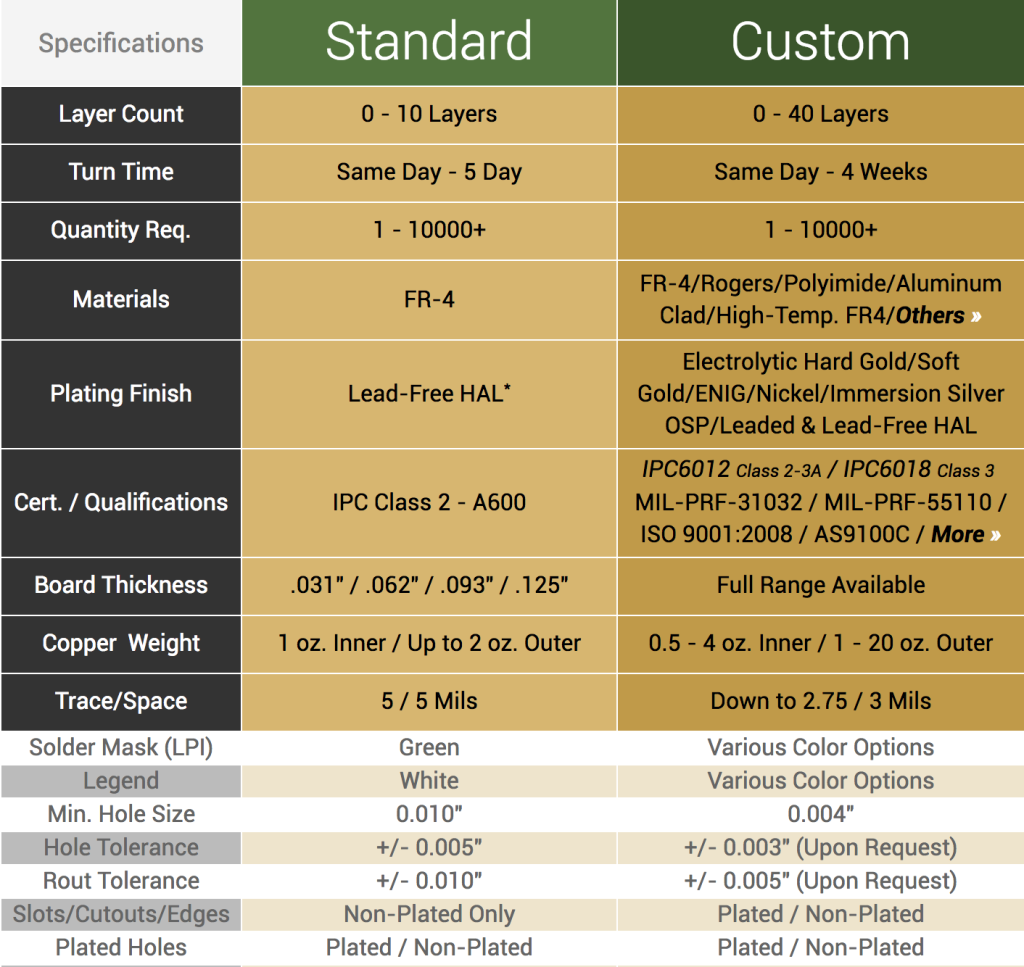

Another way Advanced Circuits helps printed circuit board design engineers optimize their designs for cost reduction is our Standard Spec and Custom Spec options. When you request an Instant Quote from My4PCB.com, you are able to compare both manufacturing options side-by-side and you are able to identify the circuit board design features or specifications that will make a difference in cost.

The partial chart above can help you compare the different circuit board design specifications that fall under our Standard Spec and Custom Spec quoting options. Click on the chart to view the complete list of specifications.

Optimize Your Circuit Board Design for Assembly

Advanced Circuits’ in-house PCB Assembly services and our hands-on approach to customer service ensure a seamless transition from PCB fabrication to assembly. This helps you save shipping and transit time from one vendor to the next and helps you avoid communication issues for assembly. To learn more about Advanced Circuits’ Assembly services, click here.

Below, we have put together a list of printed circuit board design tips to help you optimize your design for PCB assembly:

- Use PCB design software that easily identifies components and exports BOM/Positions.

- Review your printed circuit board design using a separate Gerber viewer or use FreeDFM to find possible manufacturability issues in your design.

- Communicate with your PCB assembly provider to ensure the PCB finish specified works best with their assembly process.

- Place the components on your circuit board design that must have a specific location first.

- Leave at least 100 mils between components and the printed circuit board edge.

- Space out your components evenly horizontally and vertically, and orient like printed circuit board components the same direction whenever possible.

- Make sure the orientation of your polarized parts is the same.

- Avoid placing your components at angles other than 0 or 90 degrees.

- When it is necessary to have components on both sides, keep sensitive, heavy, or through hole components on the primary side. Also, any components that need special attention should be kept on the primary side of the printed circuit board as well.

- When possible, try to minimize trace lengths.

- Consider the volume of the run. If you have a low volume then PCB assembly by hand is a viable option. If you have a high volume run, it is most cost efficient to use automated printed circuit board assembly. Also, the volume is not only determined by the number of printed circuit boards ordered but also by the number of components on each PCB.